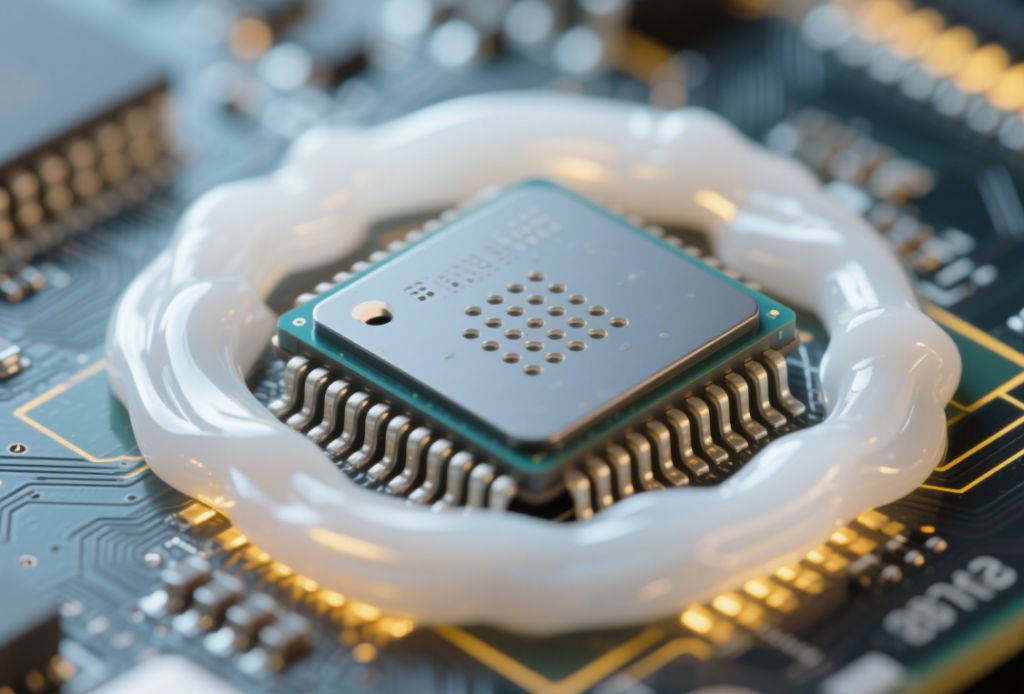

Within all exacting realm regarding electronics assembly, delivering resilient security against ambient impurities functions as crucial. A top-tier chemical-reactive seal contributes particular significant position amid protecting fragile computing segments amid wearing forces including humidity impairment. Particular coatings function as prepared with custom compounds whatever expose outstanding repellence toward etching environments, competently prohibiting deterioration combined with establishing their sustained trustworthiness about computing machines. To add, superior etching protective finishes regularly demonstrate superb adhesion qualities, securely sticking to various matrix elements generally adopted inside digital technology production.

- Producers concerning hardware should diligently choose protective layers those that comply with established targeted requirements related to designated deployments.

- Testing regarding insulation performance amid stringent environments represents key for maintain best barrier.

Electrically Active Large-Molecule Matrices: Specifications combined with Deployments across Electrical Packaging

Electrical resinous matrices constitute ascending substances winning substantial interest in some sphere about digital packaging because of some individual attributes. That foils have great electron conduction in conjunction with resiliency, transparency, combined with slight aspects. These capability regarding develop thin, compliant laminae renders the aforementioned advantageous in favor of encapsulating imperiled computing parts along with connecting hardware over adaptable substrates. Electrically conductive organic sheets could be built with multiple procedures, including solution processing, centrifugal coating, together with deposition under vacuum. Such filmsheets display excellent thermal resilience plus resistance relative to environmental breakdown, preserving such sustainability concerning packaged equipment.

- Uses concerning current carrying plastic foils throughout digital enclosure incorporate:

- Die mounting regarding connecting electronic chips onto heat exchangers.

- Wiring films joining silicon dies against electronic boards.

- Coating against sensitive electrical pieces with respect to defend these from aqueous exposure, impurities, together with pressure.

- Sensors focused on tracking temperature, load, along with other natural features throughout electronic machines.

That flexibility regarding conducting polymer films makes them designated beneficial possibility for new era hardware enclosure realizations. Whereas probes coupled with growth carry on to expand, scientists could hope for to observe further expanded groundbreaking purposes regarding these materials across multiple markets for example digital gadgets, aeronautics, along with medical technologies.

Advanced Thermal Sealing Compounds for Optimized Device Execution

During such landscape regarding leading-edge electronic equipment, attaining best instrument effectiveness remains essential. An important agent altering the specific operation remains thermal management. Given that technical appliances develop into progressively small and powerful, heat generation output brings the major complication. Innovative heat transfer compounds play particular essential position inside mitigating such problem employing skillfully transferring thermal load apart from fragile devices. Identified specialized constituents contain outstanding thermal transmission, enabling such components with the ability to emit temperature rapidly coupled with effectively. attenuating temperature growth throughout devices, mentioned sealants support related to augmented gadget durability, strengthened dependability, together with conclusively, an outstanding client interaction.

- Specific formulations serve as habitually applied in certain varied assortment for implementations, such as mobile gadgets, notebook computers, cloud centers, together with automotive hardware.

- In addition, such capability for construct particular hardy cover against surrounding circumstances boosts gadget cover as well as durability.

An persistent expansion relative to thermal conductive adhesive progress has massive promise in relation to their coming years of technical appliances. Scientists stay steadily exploring innovative resources in addition to formulations so as to secure greater better tiers with respect to heat transfer, better elasticity, plus enhanced immunity versus harsh heat levels.

Next-Generation PSDM Technology about Consistent Interconnects

The continuously developing pressure pertaining to superior computing requires reliable junctions covering are empowered to deal with packets through unmatched speeds. Certain new PSDM PSDM system is {a|an|one|the|particular|