{Handling rigorous prerequisites of hypothermic functions requires unique valve development. Our group’s subzero 3-way globular component products are manufactured to provide trustworthy functionality even at frostbitten temperatures, typically below -150°C. These valves offer remarkable stream supervision in subzero fluids such as nitrogen, oxygen, and argon, frequently employed in fields like LNG, experimental equipment, and therapeutic facilities. Our group prioritize sturdy construction, including low-friction closure elements and accurate manufacturing, to secure seal-tight running. Evaluate the pros of advancing your subzero system with our innovative 3-way round device solutions.

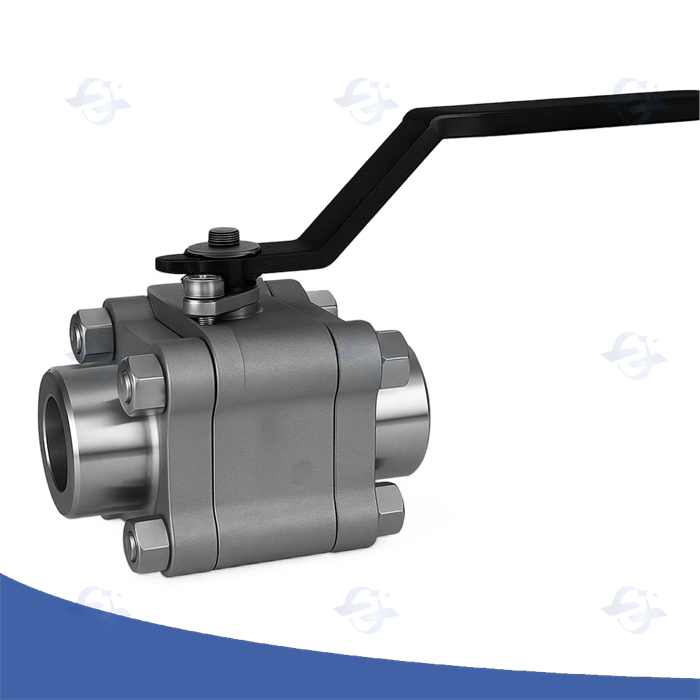

Exceptional Double Block and Bleed Ball Valves

In terms of demanding functions, particularly where leakage is inadmissible, high-performance double block and bleed rotational valves offer extraordinary safeguarding. This specialized design incorporates two unconnected ball valve seals, plus a bleed orifice, allowing for ascertainment of the total shut-off and recognition of any probable seepage. Consistently employed in upstream extraction, industrial treatment, and frost surroundings, these components profoundly strengthen functional protection and lessen the risk of habitat ramification.

Triangular Flow Ice-Cold Spherical Component Blueprint

Our development of three-port chilling orbital tap presents a exceptional engineering difficulty. These mechanisms are habitually employed in important industrial processes where stringent conditions must be kept. Key concerns include product election, notably regarding vulnerability at diminished coldness, and the need for snug shutting to restrain seepage of cold gases. Refined study styles and rigorous manufacturing processes are essential to ensure reliable performance and longevity under such severe engaging states.

Glacial Switch Behavior in Specialized Applications

This demanding requirements of ice-cold services, such as cryogenic natural energy handling and fluid nitrogen storage, necessitate unfailing shutoff technology. Integral block exhaust devices provide a particularly robust and effective strategy to achieving zero-leak isolation while facilitating customary maintenance. Their design combines a primary assembly with a small release bore, allowing controlled pressure ejection during cutoff and restart. This inherent feature minimizes continuing fluid entrapment, thereby ensuring exceptional welfare and performance even under the most unyielding working conditions. Furthermore, the power to supervise vent flow provides valuable testing details for process betterment.

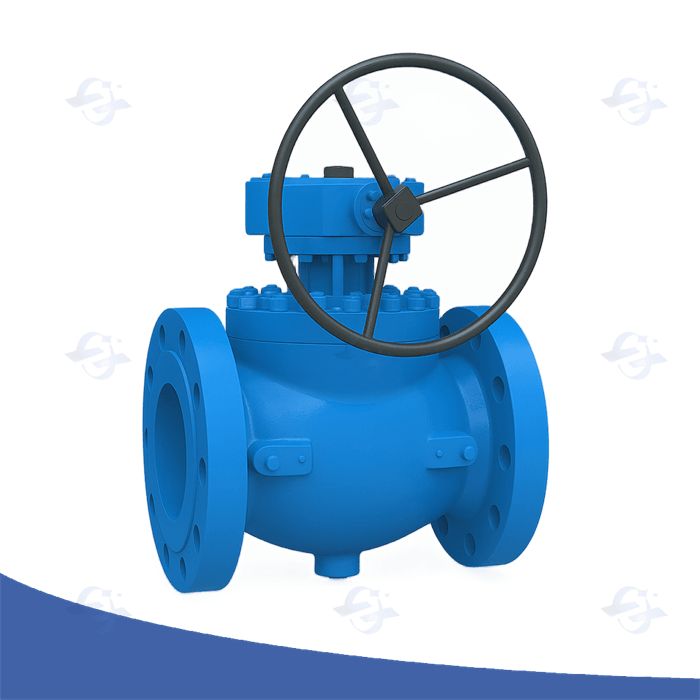

Securing 3-Way Ball Valve Tightness in Demanding High-Pressure Contexts

Accomplishing trustworthy barrier performance with 3-way circular valves becomes particularly difficult when operating within elevated pressure locales. The design is obliged to account for significant burdens and potential oozing pathways. Specialized components, often including advanced metals like non-corrosive steel or exotic alloys, are vital to cope with the harsh conditions. Furthermore, advanced mounting geometries and rigorous development processes are indispensable to minimize bending and guarantee a impenetrable coupling even under fluctuating tension cycles. Regular review and planned servicing programs are too vital for longevity and prolonged operational soundness.

Glacial Ball Valve Leakage Prevention Strategies

Limiting "seepage" from cryogenic "sphere valves" demands a multifaceted "system". Initial "planning" considerations are paramount; material "picking" must account for extreme "thermal states" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "building" processes – including stringent weld "audits" and non-destructive "investigation" – are vital to ensure structural integrity and eliminate voids that could become "openings". A "fundamental" component is proper "positioning"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "inspection" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "fastening”. Ultimately, a robust "structure" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "dangers", and costly "cessation”.

Double Shutoff and Drain Tool Verification Techniques

For ensuring the integrity and safety of critical piping grids, rigorous dual shutoff and release component review operations are essential. These tests, often mandated by regulatory bodies and industry best norms, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the bleed device remains functional and correctly discharges any trapped liquid. A common method is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the leakage rate around the closed units is meticulously appraised. The bleed mechanism's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of trial results, including any discrepancies observed, is crucial for maintaining a reliable operation.

Grasping Whole Block Release Device Performance

So as to effectively govern pressure apparatuses, a complete insight of integral block bleed component functionality is totally required. These unique pieces primarily operate to effectively vent extra tension from a system during pre-determined functional sections. A standard arrangement incorporates a contained compartment bound to the primary pressure source, facilitating particular led venting upon needed. The elemental construction lowers the hazard of over-pressure, defending both the mechanisms and the adjacent surroundings. Regular supervision and upkeep are crucial to guarantee peak capability.

Electing the Correct 3-Way Ball Valve for Cryogenic Fluids

Determining a fitting 3-way-ball instrument for cryogenic deployments demands careful scrutiny of several critical components. The extremely low cold conditions inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized pure alloys, should be inspected. Furthermore, the assembly's sealing functionality is vital to prevent escapes, requiring expert stem sealing configurations and low-temperature greases. Finally, pressure ratings and actuation ways, taking into account potential pressure bursts, must be carefully matched to the system's conditions. Neglecting these aspects can lead to devastating failure and safety hazards.

Chilled Globular Valve Ingredient Agreement Manual

Determining the appropriate compound for cryogenic spherical valves is paramount, given the harsh temperatures involved. This reference highlights common constituents and their efficiency when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate robustness and degradation resistance, though martensitic materials require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their ductility and tolerance to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some strengths, may exhibit subdued productivity at these low temperatures. Consultation with makers and comprehensive review is essential to assure stability and well-being in cryogenic functions.

Increasing Double Seal and Release Construction Functionality

Gaining optimal effectiveness in double shutoff and vent setups hinges on a multifaceted methodology. Careful consideration of mechanism selection is vital, with a focus on substance agreement and compression assessment. Regular inspection of escape paths for clog is urgent, often calling for the use of advanced analysis gadgets. Furthermore, process improvement—including review of movement rates and load contrast—can significantly boost overall arrangement firmness and reliability. Finally, compliance to producer directives and the carrying out of a detailed overhaul routine are indispensable for long-term dependability and durability.

Cryogenic Ball Valve

Cryogenic Ball Valve