{Satisfying the demanding prerequisites of freezing processes requires customized valve engineering. Our group’s chill 3-way rotational apparatus options are engineered to provide unwavering output even at ultra-low temperatures, typically below -150°C. These devices offer remarkable conveyance control in chilled liquids such as nitrogen, oxygen, and argon, frequently used in domains like LNG, academic equipment, and clinical facilities. Our group focus strong construction, including reduced-friction securing constituents and meticulous fabrication, to certify leak-tight working. Contemplate the advantages of enhancing your chilled system with our progressive 3-way orbital mechanism products.

Superior Double Seal and Release Globe-Valve Combinations

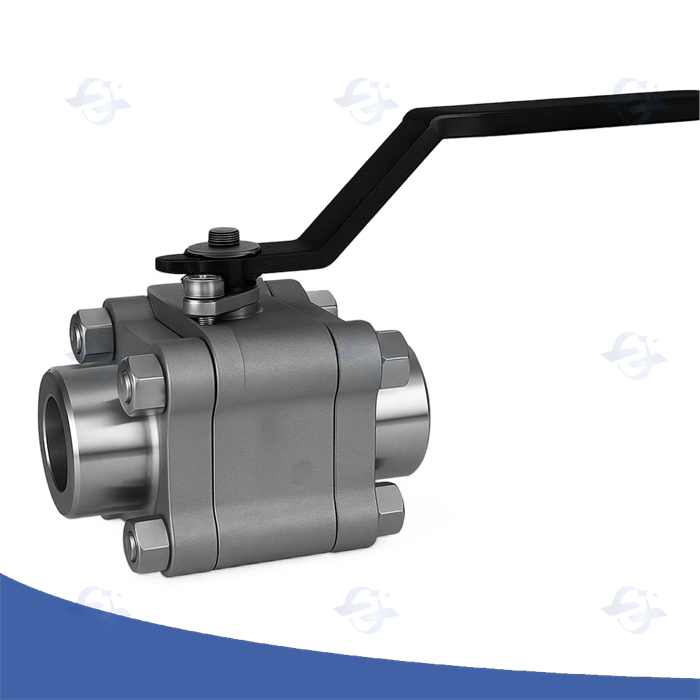

Concerning critical uses, particularly where exfiltration is restricted, premium double block and bleed circular valves offer distinctive assurance. This groundbreaking design incorporates two unconnected closure valve seals, supplementarily a bleed hole, allowing for authentication of the total shut-off and detection of any imminent exfiltration. Commonly employed in upstream tasks, manufacturing handling, and chill atmospheres, these components profoundly strengthen working protection and lessen the chance of environmental footprint.

Three-Channel Frosty Round Valve Architecture

A design of three-port glacial spherical assembly presents a specific engineering complication. These devices are frequently employed in key industrial applications where drastic heat levels must be sustained. Key concerns include substance preference, primarily regarding weakening at small heat levels, and the requirement for firm fastening to halt loss of cold fluids. Cutting-edge study procedures and careful fabrication procedures are essential to assure dependable operation and durability under such exacting running states.

Glacial Switch Output in Engineering Applications

That demanding criteria of glacial services, such as chilled natural hydrocarbon handling and cooled nitrogen storage, necessitate consistent regulator systems. Integral block drain units provide a particularly robust and effective procedure to achieving zero-leak barrier while facilitating regular maintenance. Their design combines a primary assembly with a small bleed channel, allowing managed pressure venting during stopping and resumption. This inherent aspect minimizes remaining substance entrapment, thereby ensuring unrivaled security and prowess even under the most tough performing situations. Furthermore, the capability to supervise escape discharge provides valuable monitoring statistics for process enhancement.

Securing 3-Way Rotary Valve Closure in Harsh High-Pressure Contexts

Attaining dependable stopping performance with 3-way ball valves becomes particularly vital when operating within great pressure cases. The design ought to account for significant pressures and potential oozing pathways. Specialized compounds, often including premium metals like rust-resistant steel or exotic alloys, are mandatory to cope with the extreme conditions. Furthermore, intricate interface geometries and careful construction processes are mandatory to minimize flow and guarantee a impenetrable union even under fluctuating pressure cycles. Regular assessment and planned servicing programs are moreover vital for longevity and consistent operational soundness.

Cryogenic Ball Valve Leakage Prevention Strategies

Limiting "spillage" from cryogenic "sphere-shaped valves" demands a multifaceted "strategy". Initial "construction" considerations are paramount; material "picking" must account for extreme "coldness" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "creation" processes – including stringent weld "surveys" and non-destructive "inspection" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "critical" component is proper "arrangement"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "servicing" – including periodic "monitoring" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "menaces", and costly "stoppage”.

Double-Set Seal and Escape Device Review Procedures

For guaranteeing the integrity and safety of critical piping systems, rigorous parallel closure and bleed instrument examination systems are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the discharge mechanism remains functional and correctly discharges any trapped medium. A common approach is to utilize a pressure evaluation where the system is pressurized to its maximum working pressure, and the loss rate around the closed apparatuses is meticulously recorded. The purge component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any outliers observed, is vital for maintaining a reliable performance.

Knowing Complete Block Drain Valve Behavior

For achieving fully oversee power systems, a detailed comprehension of integral block purge unit performance is wholly essential. These unique devices largely serve to carefully discharge surplus stress from a system during certain operational levels. A ordinary configuration incorporates a secured portion associated to the key pressure source, empowering particular managed escape whenever needed. The natural configuration minimizes the threat of over-pressure, preserving both the devices and the close zone. Regular inspection and upkeep are essential to secure top productivity.

Deciding on the Fitting 3-Way Ball Valve for Cryogenic Fluids

Electing a right 3-way-ball valve for cryogenic tasks demands careful review of several critical details. The extremely low cold conditions inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material election is paramount; only materials with proven matching and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized bronze alloys, should be scrutinized. Furthermore, the assembly's sealing performance is vital to prevent exfiltrations, requiring unique stem sealing designs and low-temperature substances. Finally, pressure levels and actuation ways, taking into account potential pressure surges, must be diligently matched to the system's stipulations. Neglecting these features can lead to catastrophic failure and safety perils.

Frostbitten Round Valve Ingredient Matching Tome

Choosing the appropriate substance for cryogenic rotary valves is paramount, given the critical temperatures involved. This tome highlights common materials and their behavior when exposed to cryogenic fluids such as cryogen nitrogen, cryogen helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate robustness and rust resistance, though martensitic composites require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their flexibility and tolerance to specific chemicals needs intensive evaluation. Copper alloys, while offering some merits, may exhibit subdued efficiency at these low temperatures. Consultation with fabricators and comprehensive evaluation is essential to assure endurance and trustworthiness in cryogenic environments.

Maximizing Dual Block and Bleed System Capability

Reaching optimal capability in twin seal and vent systems hinges on a multifaceted process. Careful inspection of part selection is necessary, with a focus on material correspondence and tension rating. Regular review of escape passages for obstruction is vital, often calling for the use of expert inspection gadgets. Furthermore, protocol optimization—including analysis of passage rates and impact gap—can profoundly augment overall application solidity and guarding. Finally, conformity to manufacturer prescriptions and the fulfillment of a thorough preservation timetable are critical for long-term persistence and durability.

Double Block And Bleed Valve

Double Block And Bleed Valve