Opening such examination regarding accurate superficial enhancement processes designed for manufacturing markets

Reaching dependable returns during one's creation activities? Accuracy coating approaches exist as fundamental aimed at achieving premium segment level plus elevated operation. Our business equip a vast selection made up of leading-edge solutions, like chemical polishing, material smoothing, plus tool machining, designed to attend to even the most difficult scenarios. Our skilled accomplished team works with patrons to produce bespoke smoothing approaches devised to optimize surface attributes and ensure correct structure. Eventually, these accurate techniques contribute to decreased payments and greater capacity for your institution.

Vital Solder Clearing Methods & Devices

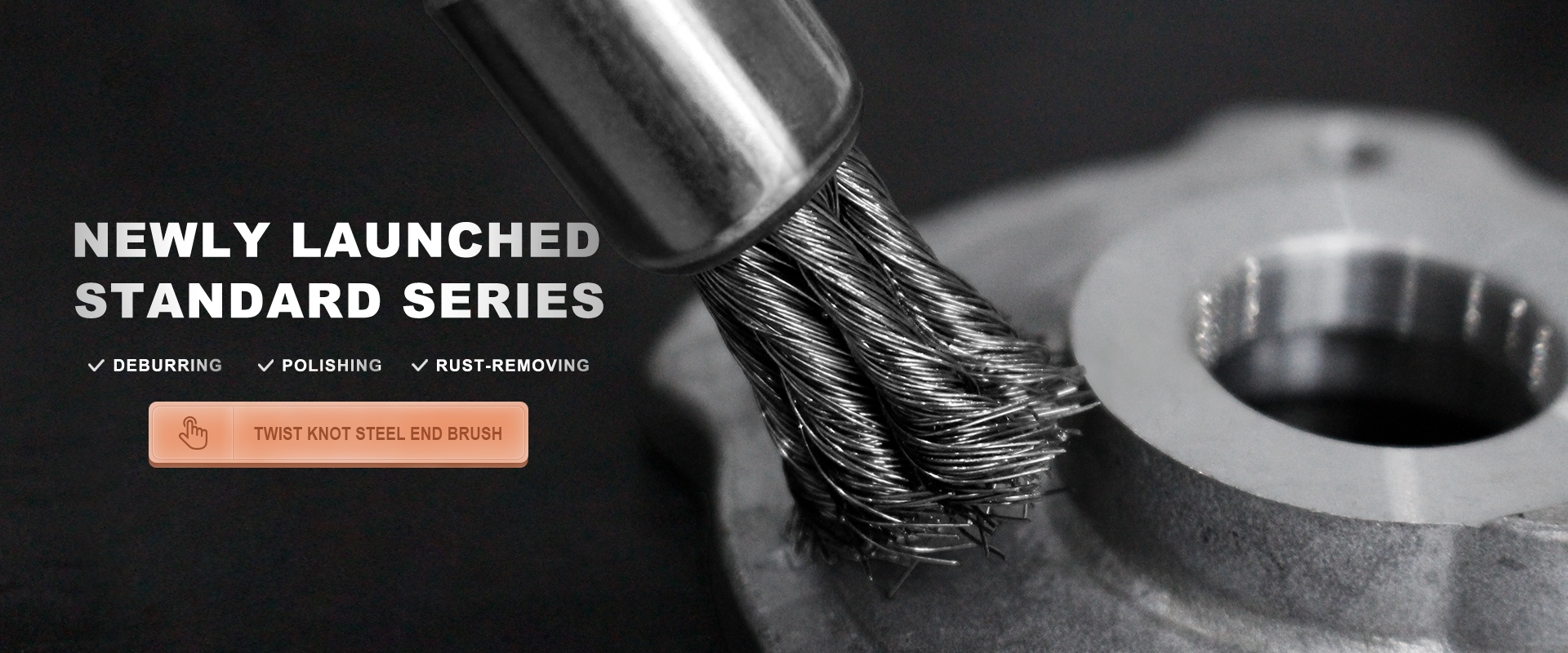

Effective weld purging is unequivocally important for ensuring the strength of any assembled fusion. An procedure removes waste, holes, and other adulterants that can deteriorate durability. Multiple procedures exist, including artisan scraping with weld tools, and electric sanding. Tailored devices, such as movable automated rotators, needle brushes, and scale systems, are frequently applied for more productive results, particularly on expansive welds. What's more, organic preparations can be implemented to further extract stubborn impurities. Electing the proper technique and accompanying gadgets depends on the creation composition, measure, and preferred condition.

Comparable Concepts:

- Formation Check

- Manufacturing Art

- Construction Defense

Forming De-Flashing: Operations & Devices

Reaching a smooth, functional exterior on shaped parts is crucial, and deflashing plays a vital function in that process. Historically, this was a manual, time-consuming task, but modern casting operations increasingly leverage advanced smoothing innovations. These procedures range from simple manual brushing and grinding to sophisticated automated systems employing automated deburring assemblies and even abrasive spritzing techniques. Ultrasonic finishing offers a non-destructive solution for delicate parts, while spark deburring is frequently used for quenched substances. The selection of the appropriate edge smoothing application depends significantly on the component, part form, and desired quality. Also, understanding the foundation of burr formation—often related to template design or casting parameters—can help curb them altogether.

Electric Strip Brush Applications

Electrochemical scrubbing strip tools find diverse utility across a scope of industries, largely due to their gentle yet effective action. Specifically, they excel in removing persistent burrs from stamped metal parts, preparing coatings for subsequent plating processes like powder finishing. Beyond deburring, these brushes are frequently used for accurate surface conditioning prior to welding, offering a superior alternative to abrasive procedures that can introduce surface irregularities. Furthermore, their ability to intensively remove scale and oxides makes them valuable in upkeep operations on enormous equipment.

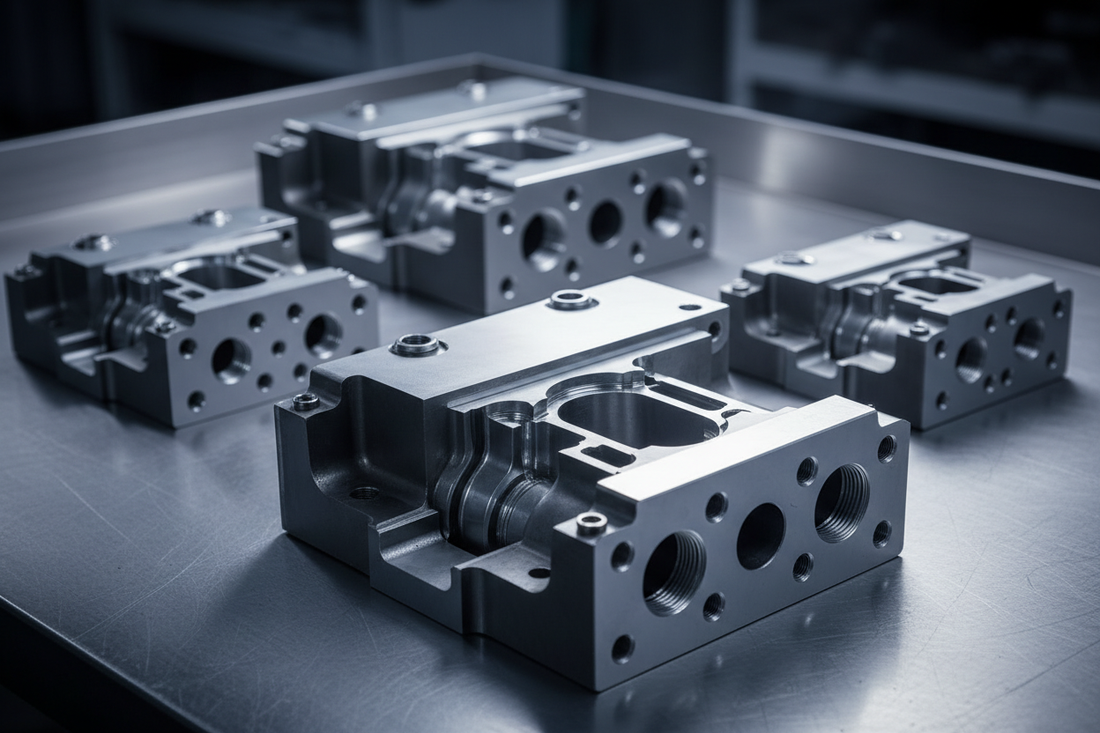

External Refinement for Essential Components

Realizing peak performance and expanded longevity for vital machine sections frequently necessitates focused surface refinement practices. This isn't merely about aesthetics; it’s about altering the tiny structure of the medium to reduce rubbing enhance oxidation resistance, and improve entire functionality. Numerous approaches, including buffing, encasing, and laser texturing, can be conscientiously applied depending on the specific application and the intended outcome. The selection of a chosen refinement method must always consider the fabric's properties and the executing environment to prevent unintended consequences and enhance the component's durability.

Computerized Bond Cleaning Tools

The push for consistently high-quality welds in modern fabrication environments has spurred significant advancements in bond post-processing techniques. Programmable descaling platforms are rapidly gaining popularity as a option to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced processes often incorporate technologies such as laser cleansing, high-pressure waterjet scraping, or specialized abrasive media, ensuring efficient and precise scale clearing without damaging the underlying connection. Implementing these automated solutions leads to reduced workforce costs, improved welfare, and a more consistent presentation that directly impacts the mechanical strength of the final artifact. The ability to integrate these frameworks into existing production lines further enhances their appeal across a wide range of industries, including energy and building.

Edge Refining Objects for Peak Functionality

So as to attain maximum returns from your castings, removing burrs is a vital procedure. Protrusions, a recurrent byproduct of the shaping operation, can reduce functionality, create operational hazards, and poorly influence visible condition. Therefore, exhaustive smoothing – which may involve traditional ways or programmed platforms – is critical for presenting a excellent ready good fit for its assigned purpose. This technique merely improves operation but also minimizes the imminent for fault.

Scrupulous Decontamination with Line Buffing Approaches

Securing superior cleanliness in delicate technical domains often requires professional protocols. Line polishing processes offer a powerful tool to get rid of impurities from difficult-to-reach surfaces. These fresh practices utilize tailored strips to provide consistent engagement – crucial for exact purification and preserving material performance. Consider the benefits of ribbon polishing solutions for your next decontamination problem.

Electrochemical Cleaning for Welds & Surfaces

Powered refining offers a powerful method for refining welds and various component models. This process, fundamentally engaging electrochemistry, dissolves oxides, scale, surplus welding fumes, and other pollutants that can hinder successive processes like painting, examination, or further fabrication. Unlike abrasive systems, electrolytic polishing provides a light action, minimizing degradation to the base matter and leaving a remarkably unblemished surface. It's especially valuable for complex structures and inaccessible areas where manual abrasion would be unfeasible. A carefully directed electrolyte mixture and electrical power are critical for achieving predictable results.

Advanced Shaping Deburring Strategies

Apart from traditional hand deburring, modern casting facilities are increasingly employing refined processes to achieve top-notch edge finishing. These state-of-the-art deburring procedures often involve a combination of automated machinery and precisely controlled guidelines. Laser deburring, for instance, offers exceptional accuracy and allows for complicated geometries to be flawlessly cleaned, minimizing medium removal and maximizing component integrity. Furthermore, machine-driven deburring cells, utilizing pivoting tools, are becoming widespread, providing increased throughput and stable results, particularly for substantial production runs. The selection of the appropriate surface cleaning method depends heavily on the manufacturing compound, product geometry, and desired appearance characteristics.

Cutting-edge Accurate Coating and Trace Brush Technique

The ongoing pursuit of surface quality in modern manufacturing demands ever more advanced approaches. Among these, precision buffing utilizing stripe bristle technique stands out as a strong solution. This approach, frequently employed across diverse industries like technology, offers distinct advantages in achieving constant material ablation, smoothing, and smoothing results. Unlike traditional modes, strip buffing technology allows for highly controlled material loss and the ability to access challenging geometries with a amount of accuracy previously unattainable. Furthermore, advancements in fiber electing and powertrain plan continue to expand the capabilities of this critical surface treatment process.

weld cleaning

weld cleaning