Beginning

Propelled differentiation methodology has emerged as a leading-edge answer for elevating garbage distribution productivity. This strategy uses the principle of projectile motion to categorize junk components based on their gravity. By flinging debris into a chamber, ballistic separation can precisely recognize various types of debris, such as plastics, metals, and biological materials. This efficient strategy to junk management can considerably augment recycling rates and reduce landfill space.

metal recycling shredderRevolutionary Substance Recuperation: The Force of Kinetic Separators

Momentum separators are upgrading the field of substance recuperation. These pioneering devices capitalize high-velocity air streams to sort substances with extraordinary accuracy. Unlike common practices, ballistic separators competently handle a wide range of elements, from plastics and metals to glass and organic waste. This multipurpose nature makes them beneficial for both considerable recycling locations and compact operations.

The intrinsic performance of ballistic separators allows a noticeably elevated recovery rate compared to conventional techniques. Furthermore, their condensed design empowers for integration into existing recycling setups with minimal disruption. As the demand for sustainable methods persists to expand, ballistic separators are set to play an rapidly important role in influencing a circular economy.

- Virtues of Ballistic Separators:

- Augmented recovery rates

- Effective material separation

- Multifunctionality for various materials

- Decreased operational costs

- Green impact reduction

Maximizing Metal Extraction: High-Performance Metal Shredders in Action

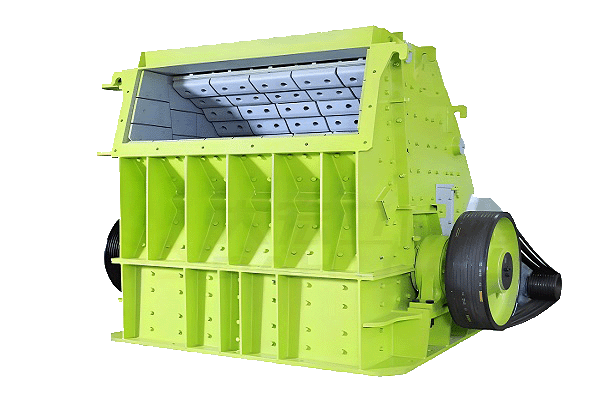

The alloy extraction domain is incessantly seeking novel ways to enhance efficiency and reduce ecological impact. High-performance metal shredders have emerged as a key method, granting unparalleled capabilities for processing immense volumes of substances. These cutting-edge machines apply innovative technology to dismantle scrap, separating valuable metals from extraneous substances with excellent accuracy.

- Besides, high-performance metal shredders are known for their durability and sturdiness, ensuring consistent performance even under demanding circumstances.

- Due to this, these machines contribute to the environment protection of metal extraction by minimizing waste and increasing resource utilization.

The integration of high-performance metal shredders is transforming the industry, stimulating advancements in metal recycling and fostering a more sustainable future.

Employing Ballistic Separators for Varied Recycling Streams

Progress in recycling innovation are significant to lessen the green effect of waste. A groundbreaking method gaining traction is the ballistic separator. This framework exploits centrifugal force to effectively sort recyclable assets based on their dimensions. By classifying materials into specific streams, the ballistic separator optimizes the recycling technique, leading to augmented recovery rates and a varied range of recyclable goods. This innovation holds immense possibility for transforming recycling approaches and supporting a planet-friendly future.

High-Tech Waste Management: Coupling AI with Ballistic Separation

The domain of waste management is rapidly evolving, driven by the pressing need to cut environmental impact. Cutting-edge technologies are being introduced to improve recycling mechanisms and build a more sustainable future. One such improvement is high-tech waste sorting, which exploits the power of ballistic separators and artificial intelligence (AI) to categorize waste substances with unprecedented cleanness.

Ballistic separators perform by using high-speed drafts to launch different classes of waste based on their size, shape, and density. This initial stage of separation lowers the complexity of the sorting mechanism for AI algorithms.

Sophisticated AI models can then understand images and data from sensors to discern specific materials with exceptional accuracy. This amalgamation of ballistic separation and AI enables a greatly efficient and optimized waste sorting system.

Refining Waste Management: A Comprehensive Guide to Waste Sorting Machines

Waste sorting is a significant step in efficient waste management. Manual sorting can be lengthy and unsatisfactory, leading to contamination and boosted costs. To address these challenges, advanced waste sorting machines have emerged as a strong solution. These machines exploit modern technology to quickly sort various waste materials into designated categories.

There are multiple types of waste sorting machines available, each designed for targeted applications. Some common types include sensor-driven sorters, which rely on magnetism to identify different materials. Also, robotic arms and conveyor belts can be assembled to sort waste with accuracy. By optimizing the sorting process, these machines considerably improve efficiency and reduce manual labor requirements.

- Strengths of using waste sorting machines include:

- Improved efficiency in sorting waste materials

- Reduced labor costs and workforce effort

- Augmented accuracy in separating recyclable materials from non-recyclable waste

- Decrease of contamination in recycling streams, leading to higher quality recycled products

- Earth-friendly benefits through boosted recycling rates and reduced landfill waste

Recycling Innovations

Established recycling operations have long been the usual procedure for classifying and processing recyclable ingredients. These methods often rely on manual separation by humans, which can be burdensome and prone to faults. However, recent advancements in technology have led to the emergence of innovative recycling procedures, such as ballistic separation.

Ballistic separation employs the impetus of impact to classify different materials based on their size, weight, and shape. This high-speed practice can accurately handle large volumes of mixed recyclables, reducing manual labor and elevating the accuracy of sorting.

Compared to traditional methods, ballistic separation offers several strengths. It is a much more systematized process, requiring less human intervention and minimizing the risk of contamination. Additionally, it can handle a wider variety of materials, such as plastics, metals, glass, and paper. This increased efficiency and flexibility make ballistic separation a useful solution for modern recycling operations.

A Detailed Look at: A Ballistic Separator for Municipal Solid Waste

This assessment examines the integration of a ballistic separator in a metropolitan solid waste management facility. The aim of this project was to advance the effectiveness of waste segregation. The study explores the functional aspects of the separator, including its layout, feeding mechanism, and division technique.

Furthermore, the evaluation evaluates the influence of the ballistic separator on waste quality.

- Data collected from the machine functioning show the performance of the implemented solution.

- Problems faced during the adoption process are also highlighted.

Tips for future betterments based on the study's findings are presented.

Maximizing Material Recovery Through Shredding and Separation Processes

In the realm of waste management, efficiently recovering valuable materials is fundamental. Shredding and separation practices play a vital role in achieving this goal. By physically reducing materials to smaller bits, shredding enables the subsequent separation stages. Advanced separation technologies, such as magnets, screens, and air classifiers, can then isolate heterogeneous material types with high effectiveness. This stepwise approach delivers a higher rate of material recovery, minimizing landfill waste and advancing a circular economy.

Choosing a Waste Sorting Machine: Key Considerations

Waste sorting technology are critical for productively managing waste and promoting reuse. When opting for a waste sorting machine, it is vital to consider several variables to ensure it meets your unique needs.

First, determine the type of waste you will be arranging. Different machines are optimized for assorted types of waste, such as plastics, paper, metals, and organic materials. Next, ponder the volume of waste you generate. This will determine the magnitude of the machine you require. A larger machine is necessary for high-volume waste streams.

Also, consider the space available at your complex. Waste sorting machines come in diverse sizes, so ensure there is sufficient room to embed the machine and allow for efficient operation. Another important element is the range of automation you require. Fully automated machines offer varying degrees of labor participation.

Finally, evaluate the upkeep needs associated with different machines. Some machines may involve more frequent repairs than others.

Maximizing Landfill Diversion Rates with Advanced Separation Technologies

Landfills are a considerable source of environmental harm. To minimize this trouble, many communities are eagerly searching for ways to elevate landfill diversion rates. Advanced separation technologies offer a promising solution by precisely sorting recyclable items from waste streams. These innovative technologies capitalize on sensors and cutting-edge algorithms to classify various objects. This leads to a greater recovery rate of recyclable items, accordingly diminishing the amount of waste sent to landfills.

The application of these advanced separation technologies can bring numerous advantages. In the beginning, it maintains natural resources by salvaging valuable materials. Besides, it reduces greenhouse gas emissions associated with waste disposal and the manufacture of new materials from raw resources.

Finishing